Aerospace

Pinette Emidecau Industries offers solutions for both manufacturing the structure and interior for the aerospace industry.

Consolidation presses for composite material

Presses for consolidation of composite materials, i.e. carbon fibre and polymer (PEEK, PEI, PPS, PEKK) with a maximum size of 2400 x 1300 mm. The final product is a composite plate, ready for thermoplastic forming process.

Presses for consolidation of composite materials, i.e. carbon fibre and polymer (PEEK, PEI, PPS, PEKK) with a maximum size of 2400 x 1300 mm. The final product is a composite plate, ready for thermoplastic forming process.

Specifications:

- Plate size: 2600 x 1500 mm

- Heating platen: 450°C

- Electric heater

- Heating rate: from 1 to 10°C/min

- Cooling rate: 10°C/min or less (non-linear)

- Total power for 2 trays: 480kW

- Type of cooling: air + water

- Guarantee temperature uniformity +/- 5°C on the surface of consolidated plates

Hot draping machine

Features:

- Infra-Red heating low inertia

- Independant movable membrane frame

- Outgoing table with vacuum equipment

- Identification preforms

- PLC control and supervision software

Large capacity NDT test bench

Features:

- Parts from 800mm to 6 metres in diameter and 6 metres in height

- Flat or revolving forms, continuous or discontinuous, driven by 14 CNC axes

- Support schemes to set up parts

- Twin captors allowing 2 simultaneous controls

- MMI on one centralised control panel

- Anti-collision devices which is supplemented by two close-up cameras

- Supplied with al full set of quick, safe to use mounting tools

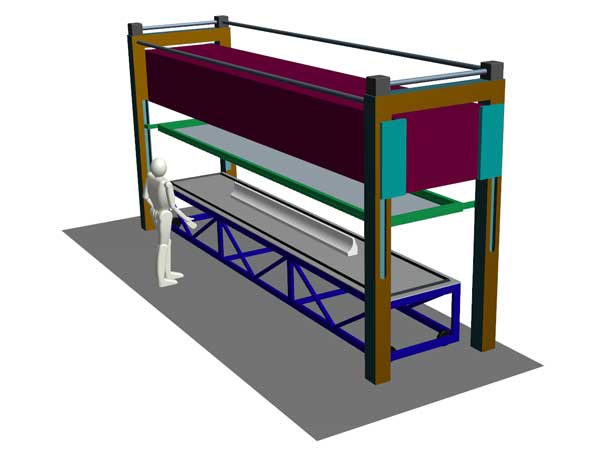

Thermoplastic parts production line

A high speed conveyor for blank loading, heating and transfer, with upper and lower IR panels and forming press with heating platen (oil or electric heating).

A high speed conveyor for blank loading, heating and transfer, with upper and lower IR panels and forming press with heating platen (oil or electric heating).

Features:

- Short cycle times

- High homogeneity of heating in IR oven

- Very short transfer time between IR even and press (less than 5s)

- High parallelism betweens platens under load

- IN TOUCH supervision software with full traceability